- Description

- Price and Availability

- Specification

- Reviews

- Videos

Description

Welding & Eyeleting in ONE pass

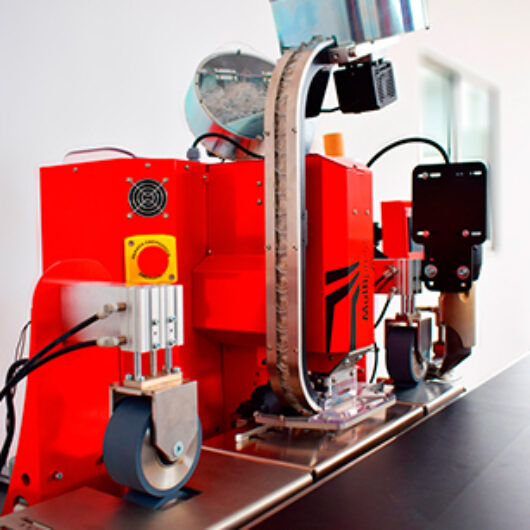

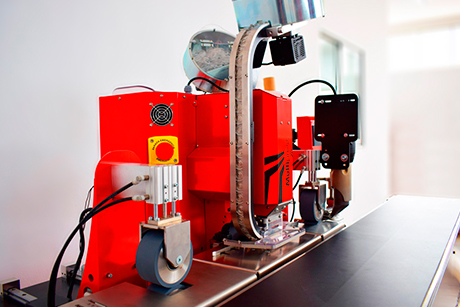

The machine that print finishing operators have been waiting for – hem welding and eyeletting in a single process.

- Unique built-in station with an automatic eyelet machine and a hot air welder.

- Banner finishing has never been so easy. Double pedal to control the operation, one to start/stop welding and the other for eyelet setting.

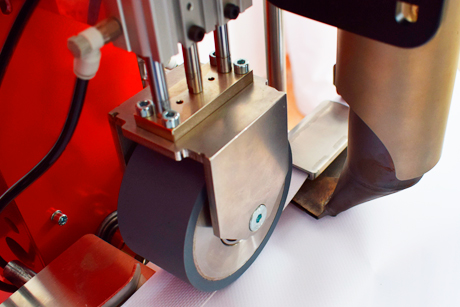

- Driven bottom synchronized rollers for consistent pressure.

- It is possible to do hem welding or just eyeletting as both machines are mounted on linear guides and can be stepped back.

- Optional conveyor system synchronized with the driven rollers for easy material handling.

Welding & Eyeleting in ONE step for any print shop

Eyeleting

| The main task for which the Finishing Station is designed is the banner finishing process with welding and eyeleting in one pass. To do this, we have installed our most advanced automatic eyelet machine, the Multipress. |  |

|

MultipressMultipress has been designed with large volume users in mind, it is fast (electric), reliable (washer and eyelet detector), features a double washer raceway, can work with fabrics as well as PVC banners and it will inform you when maintenance is due, a must-have for companies finishing a large number of banners. It can work with different types of materials: fabrics, corrugated plastics, clear foil, PVC banners… |

Welding

| Different welding options. With “The Finishing Station” you can finish your banners using keder, tap reinforcement or hem welding.

Welding and Eyeleting at the same time is possible using this station. |

|

|

Top-of-the-range hot air blower:

|

It is possible to do hem welding or just eyeletting as both machines are mounted on linear guides and can be stepped back

|

|

Technologies and Features

Additional options

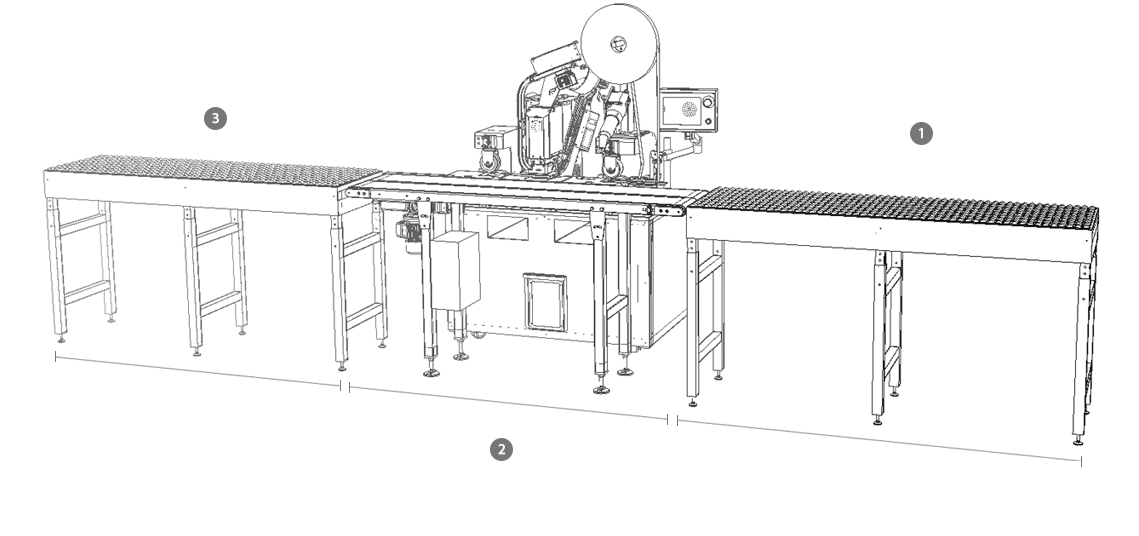

| We have two types of tables. A conveyor belt that is driven when you drive the machine. And a Extension Table that can be put before and after the conveyor belt.

Conveyor Belt: An automatic action table that will provide you with the best help and comfort to work. This table is connected and synchronized with the Finishing Station. Extension Tables: Auxiliary table designed to be placed before and after the conveyor belt. |

|

Conveyor Belt

|

Extension Tables

|

With us, your company is covered

GuaranteeEuropean manufacturing. |

Technical SupportPLASTGrommet has a professional team to give you technical support. |

ReliabilityEquipment made to last. Your print finishing department runs 24h on pick seasons and reliability. |

Safety firstThe system integrates security measures to avoid injuries and in case of any problem the machine will stop and displaying a warning message. |